Have you ever wondered what sound waves actually do to metal cylinders, producing the enchanting melodies of a saxophone or the thunder of a cannon? In this article, we’ll show you how sound waves interact with metal.

The fascinating dance of vibrations and resonances results in sound waves produced by metal cylinders. When you strike a metal cylinder or introduce it to an energy source, it generates sound waves that resonate through the material. The problem isn’t solved by this one; it’s just the tip of the iceberg. The following paragraphs will go over more in-depth mechanics, looking at how different factors influence the generation of these waves, their applications across various industries, and the promising research avenues that await them.

Please excuse my haste; if you’ve ever wondered what is actually happening in the world of sound waves in metal cylinders, this article will provide you with a fascinating insight into the world of sound waves in metal cylinders, revealing their mysteries one layer at a time. Here’s to a sonic adventure together.

Contents

The Basics of Sound Waves

In the realm of physics, there exists a phenomenon that captivates our auditory senses and fuels our appreciation for music, communication, and the natural world around us. This phenomenon is none other than the intricate web of vibrations we call sound waves. To truly grasp the marvel of sound waves, one must venture into the fundamental underpinnings of their existence, and that’s precisely what we intend to do in this exploration of the basics of sound waves.

Sound waves, at their core, are the vibrational ripples that propagate through a medium, be it air, water, or even solid materials like metal. These waves are the tangible manifestations of the invisible energy of sound, and they are what allow us to hear the world. Imagine standing in front of a musical ensemble, the strumming of guitars, the beat of drums, the melodic notes of a violin – all these sounds are, in essence, orchestrated patterns of vibrations that travel as sound waves to reach our ears.

Sound waves possess several intrinsic properties, each contributing to the rich tapestry of auditory experiences we encounter daily. Frequency, one of the key attributes of sound waves, determines the pitch or tone of a sound. It’s akin to the musical notes on a scale. Higher frequencies translate to higher-pitched sounds, while lower frequencies produce deeper, bass-like tones. Think of the delicate notes of a flute versus the earthy resonance of a double bass. These variations in frequency are the very essence of music.

Another vital characteristic of sound waves is amplitude, which corresponds to the wave’s intensity or loudness. If we were to equate sound waves to a storyteller’s voice, amplitude would be the storyteller’s volume control. A wave with greater amplitude carries more energy and is perceived as louder, while a wave with lower amplitude produces a softer, more gentle sound. This property of sound waves is why a whispered secret differs so markedly from a thunderous declaration.

Wavelength is the next player in this symphony of characteristics. It defines the spatial distance between consecutive wave peaks (or troughs) and plays a crucial role in determining how a sound wave propagates through various mediums. Wavelength is inversely proportional to frequency, meaning that as frequency increases, wavelength decreases. This relationship is akin to the rhythm of a drumbeat; the faster the drum is beaten (higher frequency), the shorter the distance between each beat (shorter wavelength).

Now, as these sound waves traverse their respective mediums, they display an extraordinary capacity to adapt and behave uniquely. For instance, in the air, which is the most common medium for sound propagation, these waves move in longitudinal patterns, compressing and rarefying air molecules as they travel. However, when sound waves encounter a denser medium, such as water or a solid substance like metal, they exhibit distinct behaviors.

In water, sound waves travel approximately four times faster than they do in air, thanks to the tighter molecular arrangement in this medium. This phenomenon is analogous to a sprinter leaping forward on a smooth track, as opposed to a rocky terrain, covering greater distances in less time. Furthermore, in the domain of solid materials like metal, sound waves navigate a dense lattice of atoms, resulting in an even higher velocity compared to water. It’s akin to a skilled surfer riding a colossal wave, exploiting the resilience of the medium to transmit energy with astonishing efficiency.

Metal Cylinders: A Unique Medium

When exploring the world of sound waves, one cannot overlook the crucial role played by a rather unassuming yet indispensable player in this auditory symphony: metal cylinders. These cylindrical structures, often underestimated in their significance, possess a unique set of properties and acoustic characteristics that make them a subject of great interest in the context of sound wave phenomena.

Metal cylinders, as the name suggests, are cylindrical-shaped objects predominantly composed of metal, known for their durability and versatility in various applications. These cylinders come in a myriad of sizes, ranging from the small brass tubing in a musical instrument to the massive metal chambers used in industrial processes. Their commonality lies in their structural shape and the material they are made of, which forms the foundation for their intriguing interactions with sound waves.

What sets metal cylinders apart and sparks our fascination is their remarkable ability to resonate and amplify sound. This property stems from the nature of metals themselves, which are excellent conductors of sound due to the tightly packed arrangement of atoms within their crystalline lattice structures. When sound waves encounter a metal cylinder, they encounter a medium that readily responds to their presence.

Metal cylinders, in the context of sound waves, are of immense interest for several compelling reasons:

Resonance Amplification: One of the most captivating aspects of metal cylinders is their propensity to resonate when exposed to specific frequencies of sound. This resonance phenomenon can lead to a substantial amplification of sound waves, transforming even a faint input into a powerful output. This property finds extensive application in musical instruments like trumpets and trombones, where the vibrations of a musician’s lips generate sound waves that resonate within the metal tubing, producing the distinct and resonant tones associated with brass instruments.

Sound Reinforcement: Beyond the realm of music, metal cylinders play a vital role in sound reinforcement systems, such as microphones and loudspeakers. The precision and reliability of metal in capturing and projecting sound waves make it an ideal material for these applications. Sound engineers and audiophiles alike appreciate the clean, uncolored sound reproduction achieved through the use of metal cylinders.

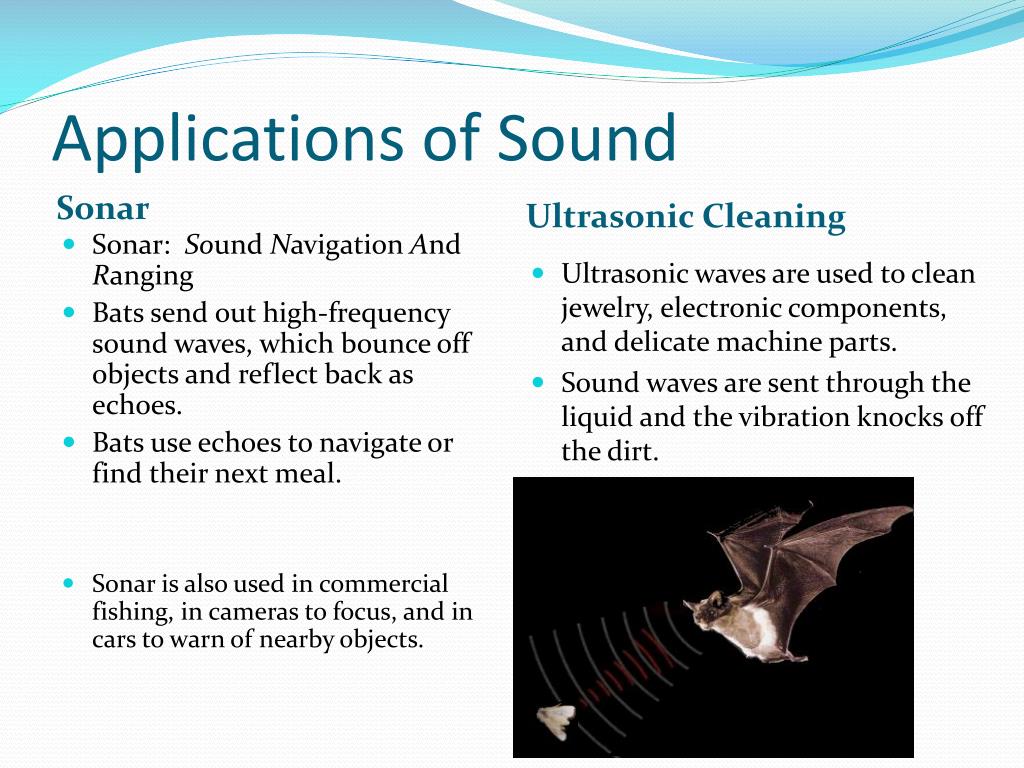

Industrial Applications: Metal cylinders also find their place in industrial settings where sound waves serve as diagnostic tools. Ultrasonic testing, for instance, employs metal cylinders to transmit and receive sound waves through materials, helping detect flaws, cracks, or inconsistencies in various objects, from aircraft components to pipelines. The ability of metal cylinders to transmit sound efficiently is a cornerstone of these non-destructive testing methods.

Highlighting the acoustic characteristics of metal cylinders, it’s crucial to recognize that their exceptional density and stiffness contribute to their acoustic excellence. The density of metal ensures that sound waves encounter minimal resistance when traveling through, resulting in minimal energy loss. Additionally, the stiffness of metal cylinders allows for precise control of the vibrations within, influencing the timbre and resonance of the emitted sound.

Sound Wave Production in Metal Cylinders

Delving into the intricate realm of sound wave production within metal cylinders unveils a captivating fusion of physics, vibrations, and resonance. To understand this fascinating phenomenon, one must embark on a journey into the heart of how sound waves come to life within these cylindrical structures.

Mechanisms behind sound wave production in metal cylinders are rooted in the fundamental principles of physics. At their essence, sound waves are a result of mechanical vibrations, and metal cylinders are adept at harnessing this energy. When an external force, such as striking a metal surface or blowing air into an instrument, sets the metal cylinder into motion, it initiates a cascade of events that culminate in the generation of sound waves.

Vibrations, in this context, play a pivotal role. As the metal cylinder vibrates, it sets in motion a series of compressions and rarefactions within the surrounding air or the material itself. These compressions and rarefactions are akin to the ebb and flow of ocean waves, creating a rhythmic pattern of high and low-pressure zones. As this pattern propagates outward from the vibrating cylinder, it generates what we perceive as sound.

But what truly elevates the phenomenon is resonance. Resonance is the tendency of an object to vibrate in harmony with an external force or frequency. In the case of metal cylinders, when the frequency of the vibrations matches the natural resonant frequency of the cylinder, something magical happens. The vibrations become reinforced and amplified, akin to a swing being pushed at just the right moment to reach greater heights. This amplification effect is what makes musical instruments like trumpets and flutes produce distinct, resonant tones when air is blown into them.

Now, let’s delve into the nitty-gritty of how energy is transferred to the metal cylinder to produce sound waves. The energy transfer begins with the initial input, whether it’s a musician plucking a guitar string, striking a metal plate, or blowing air into a brass instrument. This input imparts kinetic energy to the metal cylinder, causing it to vibrate. The kinetic energy is then transformed into potential energy as the cylinder reaches its maximum displacement from its resting position.

As the metal cylinder oscillates back and forth, it continually exchanges kinetic and potential energy, creating a continuous cycle of vibrations. These vibrations propagate through the metal, creating compressions and rarefactions in the surrounding air. The transfer of energy from the metal to the air molecules is what we perceive as sound. It’s akin to a rhythmic dance where energy is constantly being transferred between the metal and the medium through which sound waves travel.

In summary, sound wave production in metal cylinders is a symphony of physics and vibrations. The mechanisms involve the initiation of vibrations within the metal cylinder, the creation of compressions and rarefactions in the surrounding medium, and the magic of resonance that amplifies these vibrations to produce the melodious tones we cherish in music. Understanding these intricate processes not only deepens our appreciation for musical instruments but also sheds light on the fundamental physics that govern the world of sound. So, the next time you hear the enchanting notes of a saxophone or the majestic resonance of a church bell, remember that it all begins with the mesmerizing dance of vibrations within metal cylinders.

Factors Influencing Sound Wave Generation

In the captivating realm of sound wave generation within metal cylinders, a multitude of intricate factors converge to shape the quality and character of the resulting auditory experience. To truly grasp the nuances of this phenomenon, it’s essential to meticulously examine the factors that wield influence over the production of sound waves within these cylindrical structures.

Cylinder Material, Shape, and Size: These three fundamental characteristics of metal cylinders play a pivotal role in determining how sound waves are generated and propagated:

Material: The choice of material significantly impacts sound wave production. Metals, known for their density and rigidity, are prime candidates for sound amplification. The crystalline lattice structures within metals allow sound waves to travel efficiently, resulting in enhanced resonance. Different metals, such as brass or steel, exhibit varying acoustic properties, leading to unique tonal qualities in musical instruments. For instance, brass instruments like trumpets and trombones owe their bright and brassy tones to the material’s specific characteristics.

Shape: The geometry of a metal cylinder also exerts a profound influence. The shape determines the natural resonant frequencies of the cylinder, which can either enhance or dampen certain harmonics. Cylindrical shapes, like those found in flutes and clarinets, produce distinct harmonic patterns that contribute to the instrument’s timbre. In contrast, more complex shapes, as seen in saxophones with their conical design, yield a broader range of harmonics, resulting in a rich and versatile sound.

Size: Size matters when it comes to sound wave generation in metal cylinders. Smaller cylinders tend to produce higher-pitched sounds due to their shorter wavelength, while larger cylinders favor lower-pitched tones. This size-dependent phenomenon is evident in instruments like the organ, where the vast array of pipes of varying lengths generates a diverse range of notes. Moreover, the size of the cylinder can influence the volume of the produced sound. Larger cylinders have greater internal air volume, allowing for more significant sound amplification.

Temperature and Pressure: Beyond the inherent characteristics of metal cylinders, external factors such as temperature and pressure can exert a profound influence on sound wave generation:

Temperature: Temperature affects the speed of sound in the surrounding medium, which, in turn, influences how sound waves interact with the metal cylinder. As temperature rises, sound waves travel faster through the air or other mediums. This can impact the timing and phase of sound wave reflections within the cylinder, potentially altering the perceived sound. Musicians often need to adjust their instruments in response to temperature changes to maintain pitch accuracy.

Pressure: Changes in pressure, whether due to alterations in altitude or external forces, can also affect sound wave behavior. Higher pressures lead to denser mediums, which, in turn, affect the speed of sound. Musicians performing at different altitudes may encounter challenges in maintaining consistent instrument tuning. In industrial applications, variations in pressure can influence the performance of ultrasonic testing equipment, requiring calibration to ensure accurate results.

In essence, sound wave generation within metal cylinders is a complex interplay of material properties, geometric characteristics, and external factors like temperature and pressure. Understanding how these elements converge is crucial for musicians seeking to master their instruments, engineers aiming to optimize industrial processes, and scientists unraveling the mysteries of acoustic physics. It’s a symphony of science and art, where every factor harmonizes to produce the melodies and resonances that enrich our auditory world.

Applications of Sound Waves in Metal Cylinders

The applications of sound waves in metal cylinders extend far beyond the realm of musical serenades, transcending into an array of industries and fields where this phenomenon serves as a cornerstone of innovation and practicality. This intricate interplay of physics and engineering has found its place in countless real-world scenarios, enriching our lives and driving advancements across various domains.

Practical Applications:

Musical Instruments: Perhaps the most renowned application of sound waves in metal cylinders is within the world of musical instruments. Brass and woodwind instruments, such as trumpets, saxophones, and flutes, rely on precisely designed metal cylinders to produce a diverse range of tones and harmonies. The resonant properties of these cylinders amplify sound waves, resulting in the rich and enchanting melodies we cherish in music.

Sound Reinforcement Systems: The entertainment industry harnesses the power of sound waves in metal cylinders to deliver immersive audio experiences. High-quality microphones and loudspeakers employ metal components to capture and project sound with exceptional clarity and fidelity. Whether it’s a rock concert or a Broadway show, the precision of metal cylinders in sound reinforcement ensures that every note and word is heard with unparalleled precision.

Industrial Testing and Inspection: In the realm of non-destructive testing and inspection, sound waves in metal cylinders find crucial applications. Ultrasonic testing, for instance, relies on the transmission of sound waves through metal materials to detect flaws, cracks, or inconsistencies. This technology plays a pivotal role in ensuring the structural integrity of critical components in industries such as aerospace, oil and gas, and manufacturing.

Relevant Industries and Fields:

Manufacturing: Metal cylinders and sound wave applications are integral to manufacturing processes. Ultrasonic welding and cutting, for instance, rely on the precise control of sound waves within metal cylinders to achieve clean and efficient results. Additionally, quality control and testing in manufacturing often involve ultrasonic inspections to ensure product integrity.

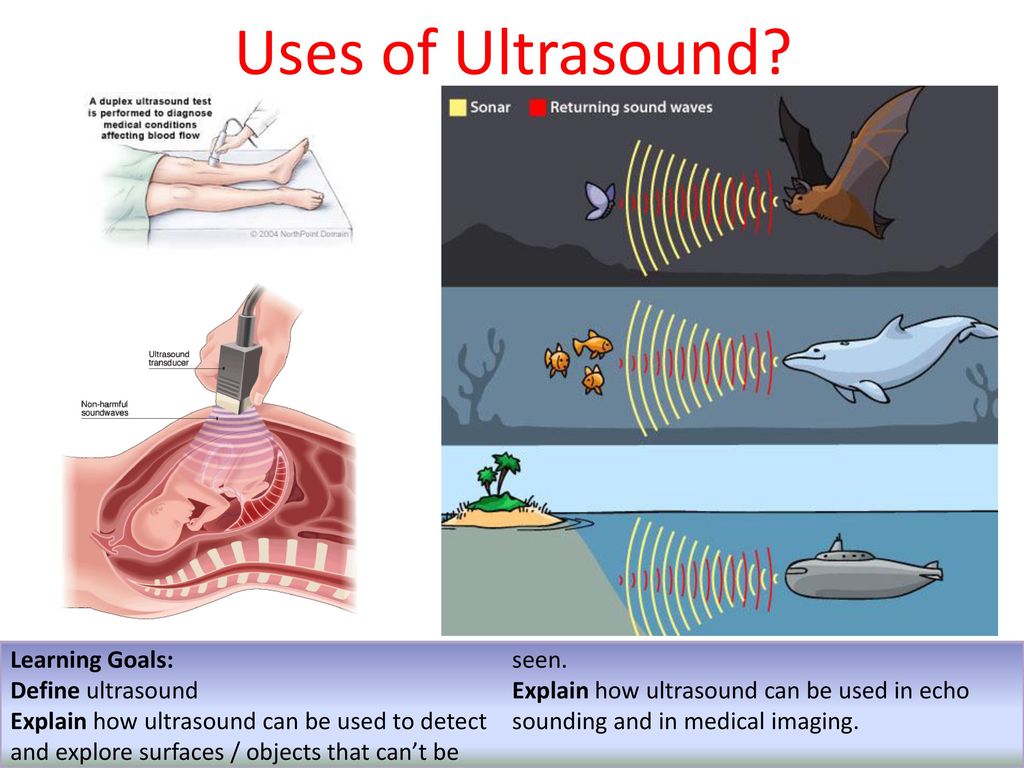

Healthcare: The medical field benefits from sound wave applications in metal cylinders, particularly in the realm of medical imaging. Ultrasound technology utilizes metal transducers to generate and receive sound waves, enabling non-invasive imaging of internal structures, from fetal development monitoring to diagnosing medical conditions.

Aerospace: In the aerospace industry, the reliability of metal structures is paramount. Sound wave technology plays a critical role in inspecting aircraft components for hidden defects or fatigue cracks. This ensures the safety and airworthiness of aircraft, safeguarding both passengers and crew.

Real-World Examples:

Medical Ultrasound: In obstetrics, expecting parents eagerly anticipate the moment when they can catch a glimpse of their unborn child through ultrasound imaging. This technology employs metal transducers to emit high-frequency sound waves into the body, bouncing off tissues and returning as echoes to create detailed images of the fetus.

Oil and Gas Pipeline Inspection: The integrity of pipelines in the oil and gas industry is essential to prevent environmental disasters and ensure the efficient transport of resources. Ultrasonic inspection tools, often equipped with metal cylinders, are used to detect corrosion or defects in pipeline walls, allowing for timely maintenance and preventing potential leaks.

Concert Halls: The architectural design of concert halls incorporates principles of sound wave propagation in metal cylinders. The shape and materials used in the construction of these spaces are meticulously crafted to create optimal acoustics, ensuring that every note from the orchestra or performer reaches the audience with crystal clarity and resonance.

Experimental Approaches

The exploration of sound waves in metal cylinders has long been an area of fascination for scientists and researchers, giving rise to a diverse array of experimental approaches aimed at unraveling the intricacies of this phenomenon. These methodical investigations are vital in expanding our understanding of sound wave production, resonance, and propagation within these cylindrical structures.

Methods Used to Study Sound Waves in Metal Cylinders:

Resonance Testing: One of the fundamental methods employed is resonance testing. In this approach, metal cylinders are subjected to controlled vibrations, either through mechanical means or acoustic excitation. Researchers carefully monitor the response of the cylinder, examining how it resonates at different frequencies. This allows for the determination of natural resonant frequencies and modes within the cylinder, shedding light on its acoustic properties.

Ultrasonic Testing: Ultrasonic techniques are invaluable for investigating the interior of metal cylinders. By emitting high-frequency sound waves into the cylinder and measuring the echoes that bounce back, researchers can create detailed images of the cylinder’s internal structure. This method is widely used in industries such as manufacturing and aerospace to assess the integrity of metal components.

Acoustic Simulation: Advanced computational tools have revolutionized the study of sound waves in metal cylinders. Acoustic simulation software allows researchers to model and simulate the behavior of sound waves within various cylinder geometries and materials. These simulations provide valuable insights into how different factors, such as shape and material, influence sound wave propagation.

Designing Experimental Investigations:

Variable Manipulation: Experimental designs often involve the manipulation of variables to isolate specific aspects of sound wave behavior. For example, researchers may vary the material of the cylinder while keeping its shape constant to assess the material’s impact on resonance. Alternatively, they might alter the shape of the cylinder while maintaining consistent material properties to study the effects of geometry.

Controlled Environments: To ensure accurate and reproducible results, experiments are typically conducted in controlled environments. This includes maintaining consistent temperature and pressure conditions to minimize external influences on sound wave behavior. Controlled environments also allow researchers to establish baselines for their experiments.

Data Collection and Analysis: Experiments involve meticulous data collection, often through sensors and specialized equipment. The collected data, such as resonance frequencies or acoustic pressure measurements, are subjected to rigorous analysis using statistical methods and computational tools. This analysis helps researchers draw meaningful conclusions about the behavior of sound waves in metal cylinders.

Key Experiments and Findings:

Chladni Plates: The study of Chladni patterns, which involve spreading fine particles on vibrating metal plates, has provided valuable insights into sound wave behavior. These patterns reveal nodal lines where the particles gather due to minimal vibration, offering a visual representation of sound wave nodes and antinodes in metal cylinders.

Resonance Tube Experiments: Researchers have conducted experiments using resonance tubes to investigate how altering the length and geometry of a cylindrical tube impacts the production of sound waves. These experiments have yielded critical data for designing musical instruments like flutes and organ pipes.

Ultrasonic Inspection: In the field of industrial inspection, ultrasonic testing has been pivotal. It involves the use of metal cylinders as transducers to generate and receive ultrasonic waves. The precise measurement of wave travel times and reflections aids in detecting structural flaws in metal components, ensuring safety and quality in various industries.

Challenges and Future Research

As the study of sound waves in metal cylinders continues to evolve, it is essential to acknowledge the existing challenges and contemplate the promising avenues for future research and technological advancements in this intriguing field.

Current Challenges and Limitations:

Complexity of Acoustic Behavior: Sound wave behavior within metal cylinders can be incredibly complex, influenced by factors like geometry, material properties, and external conditions. Understanding and modeling this intricate behavior remain challenging, particularly in non-standard geometries or when dealing with materials exhibiting unique acoustic characteristics.

Experimental Precision: Conducting experiments to investigate sound waves in metal cylinders demands a high degree of precision. Ensuring controlled conditions, accurate measurements, and consistent results can be labor-intensive and may require specialized equipment and expertise. This poses challenges, especially in resource-constrained environments.

Interdisciplinary Nature: Research in this field often spans various disciplines, from physics and engineering to materials science and acoustics. Bridging the gap between these diverse domains and fostering collaboration among experts can be challenging but is crucial for advancing knowledge and solving complex problems.

Potential Areas for Future Research and Technological Advancements:

Advanced Materials: Exploring novel materials with tailored acoustic properties could open new frontiers in sound wave manipulation within metal cylinders. Engineered materials designed for specific applications, such as enhanced resonance or improved sound absorption, could revolutionize industries like music, transportation, and manufacturing.

Nanotechnology and Miniaturization: The miniaturization of sound wave devices and components holds immense potential. Researchers can delve into the development of nanoscale metal cylinders and acoustic structures, enabling innovative applications in fields like medical imaging, sensor technology, and communication.

Artificial Intelligence and Simulation: Leveraging artificial intelligence (AI) and machine learning algorithms can streamline the analysis of complex acoustic data and aid in the design of optimized metal cylinder geometries. Simulation tools, powered by AI, can accelerate research by predicting sound wave behavior in various scenarios.

Environmental Considerations: With an increasing focus on sustainability, future research may explore environmentally friendly materials and acoustic technologies. This could lead to the development of eco-conscious musical instruments, energy-efficient sound systems, and eco-friendly industrial processes.

Biomedical Applications: Sound waves in metal cylinders have significant potential in the biomedical field. Research may delve into non-invasive medical treatments and diagnostics, using focused sound waves to target specific tissues or organs, as well as advancing the capabilities of medical imaging techniques.

Integration with IoT: The integration of sound wave technologies in the Internet of Things (IoT) ecosystem could pave the way for innovative applications, such as smart buildings that use sound wave-based sensors for security and monitoring, or intelligent transportation systems that rely on acoustic signals for vehicle communication.

Hi, my name’s Jamie. I’m a teacher and graduate in acoustics & music. I’m passionate about all things sound related, and I hope that comes across on the website.

Please get in contact if there’s anything we can do to help.